Blog | 11 Nov 2022

Construction industry leaders tackle stagnant productivity

Graham Robinson

Global Infrastructure and Construction Lead

Historically, the UK construction industry has a reputation for a lack of transparency and trust. In order to combat this, we have joined some of the UK’s leading developers, contractors, architects, engineers, professional services providers and suppliers within the construction sector to create the ‘Trust and Productivity: the private sector construction playbook’ which evaluates how the construction and design teams can work in a more collaborative way to boost productivity, quality and value and in doing so reduce carbon emissions and improve the health, safety and wellbeing of the workforce.

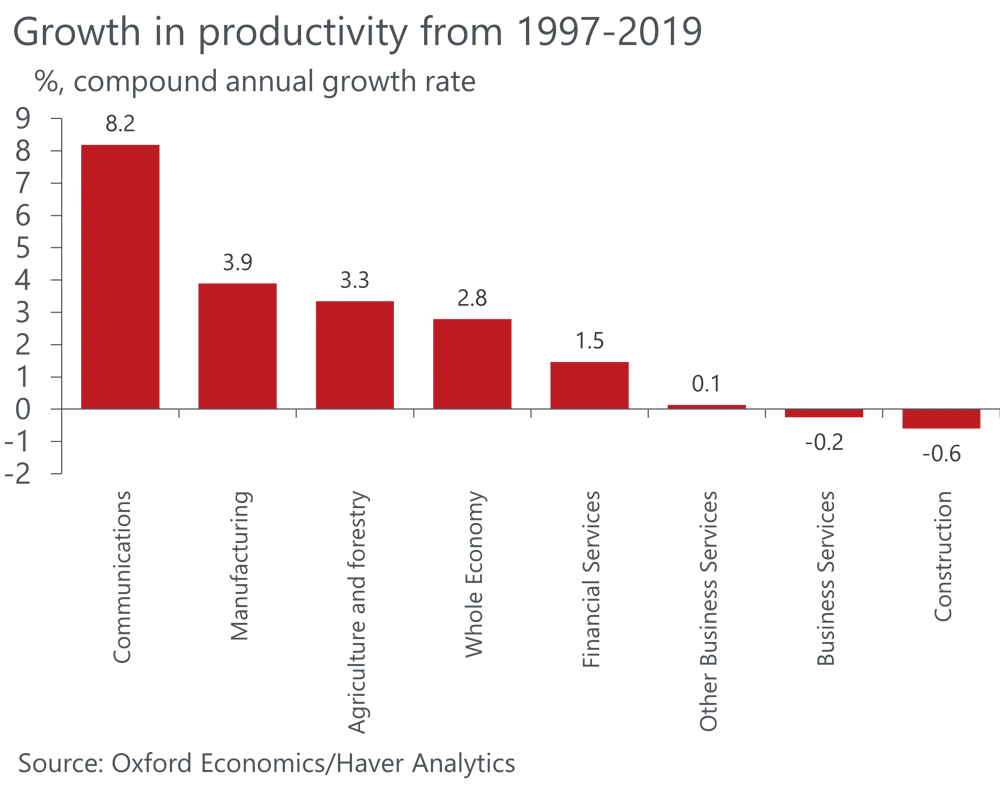

“The need for action is clear: UK construction productivity growth fell by an average of -0.6% each year between 1997 and 2019 according to Oxford Economics. Over the same period, the productivity of the whole UK economy rose by 2.8%, while the productivity of manufacturing grew by 3.9%. In real terms, this means that a larger workforce is now required to match historical output, making construction increasingly expensive and leading to a downward spiral of low margins and low investment. Operating under such conditions makes innovation more challenging.” Graham Robinson, Global Infrastructure and Construction Lead

The ten drivers, outlined in the playbook, are:

- Form effective partnerships: Project failure is often down to three factors: teams not collaborating effectively; team members pulling in different directions; and too much risk unfairly loaded onto one of the parties to a contract, thereby creating tension and mistrust from the start. To avoid failure, defined goals need to be agreed at the outset that sets out clearly the shared objectives, values and measures of success.

- Adopt portfolio and longer-term contracting: Historically, there has been a perception that partnering-based approaches do not deliver value and can stifle innovation. However, when applied in a transparent way, partnering can deliver value and drive innovation. It can also provide consistency, improve quality and reduce risk.

- Take an outcome-based approach: This requires that the client and the supply chain agree at the outset on what they are trying to achieve. To be successful, the client must clearly articulate their vision for the project

- Embed digital information flows across the whole life of the asset: Increased use of digital information processes and technologies will reduce programme time and whole-life cost, and enable buildings to be delivered more cost-effectively while reducing risk and enabling the smart use of buildings during operation.

- Involve the supply chain early: Early supply chain engagement is critical to improving productivity within the construction process and the supply chain should be encouraged to explain and demonstrate additional value opportunities. This is particularly important where the input includes a design element.

- Benchmark objectives: This is integral to an outcome-based approach. It enables those involved in a project to agree on performance targets right at the start. This should produce better decision-making and accountability

- Allocate risk fairly and appropriately: Using experience, expertise and knowledge; the party best placed to manage the risk should take the leadership role and should also encourage collaborative thinking among all parties.

- Pay fairly: Payment mechanisms must be put in place right at the start and have buy-in from the supply chain. Trust and collaborative partnerships can only be established if fair payment is in place. Best practice, as set out in the Construction Act 2011 amendment, should be adhered to at the very least, and embedded in all construction contracts, with any amendments taking into consideration supply chain implications and risk allocation.

- Assess the economic and financial standing of suppliers: Minimising the risk of failure in the supply chain is crucial for the efficient delivery of a project. The financial strength of all supply chain partners should be assessed during the selection process. Assessments should be transparent, objective and non-discriminatory.

- Promote innovation and continuous improvement: Innovation through using digital information processes and digital technology, adopting modern methods of construction and designing for manufacture and assembly can improve productivity, reduce waste and drive significant reductions in lifetime carbon emissions.

The actions outlined above will enable productivity in the construction industry which, in turn, will play a vital role in economic growth and support the UK’s green economy initiatives.

Tags: